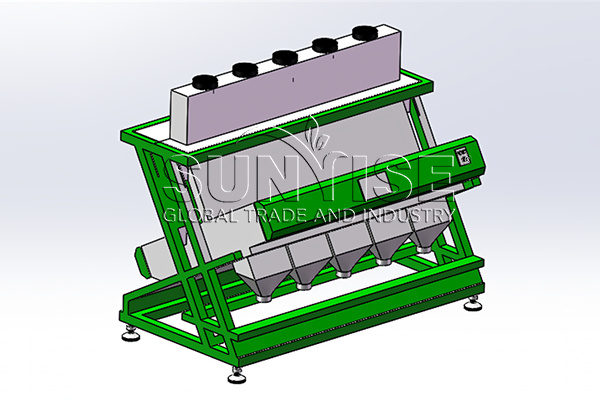

You can often utilize a color sorter as a material sorter. In addition, it is also used to separate and screen miscellaneous impurities or materials in the material that do not meet the requirements. All in all, the color sorter can quickly and automatically sort the material, which not only improves the production efficiency and output, but also improves the purity and quality of the material.

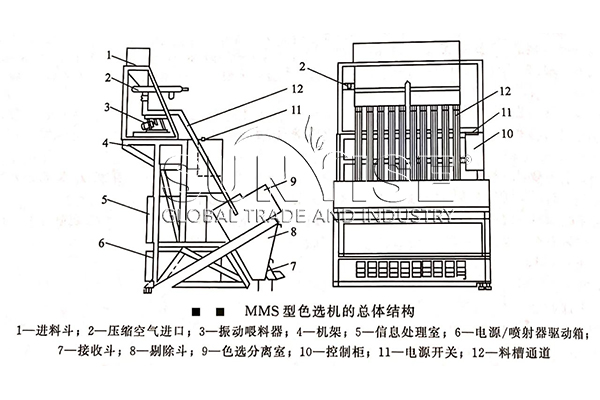

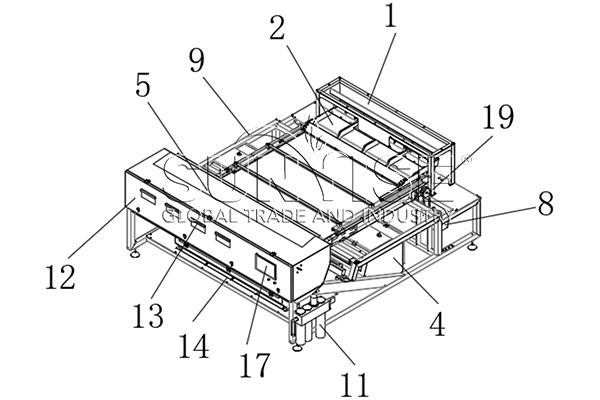

The system consists of 6 major color sorter.

Induction detection system

The induction detection system mainly includes light sources and sensors. Therefore, the light source illuminates the material, while the sensor detects the color information of the material through photoelectric sensing technology. Thus,it can convert it into an electrical signal.

Sorting system

The separation system comprises not only a strong light source system but also an air injection system. Therefore, a strong light source can be used to enhance the color difference of the material. On the other hand, the air injection system is based on the color information detected by the sensor. So it can separate materials of different colors by controlling the switch of the injector.

Collection system

You can use the collection system to collect sorted materials and impurities. Generally, there are multiple collection channels to collect materials and impurities of different colors.

Control system

The control system is the core part of the color sorter, used to control the operation of each system and coordinate the work of each component. By setting parameters and adjusting parameters, the control system can achieve precise control of the sorting process.

Conveying system

What categories can color sorter be divided into?

Color sorter can divide into four categories, as described below.

According to technology

It includes traditional photoelectric sorting machine and CCD technology sorting machine. In addition, there are infrared technology sorters and X-ray sorters.

According to light source

In short, it not only includes fluorescent tube wide source color selection machine, LED light source color selection machine and microwave light source color selection machine. Moreover, it also includes X-ray color sorting machines.

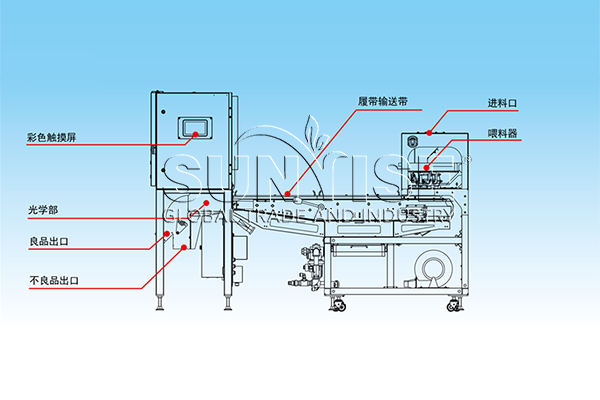

According to the frame

It includes not only waterfall type but also track type.

According to materials

For example,rice color sorter, grain color sorter, tea color sorter, etc.

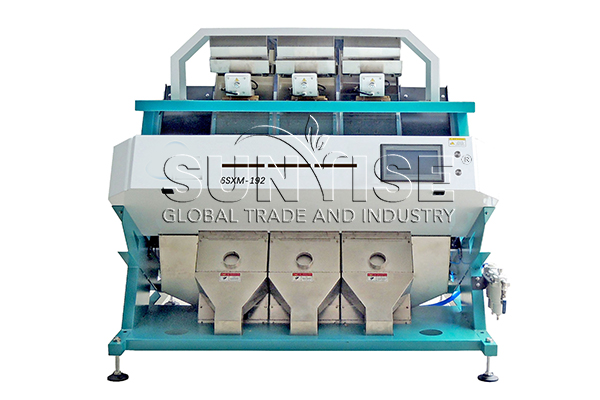

Why choose our color sorter?

Our color sorter is worthy of your trust and choice. And then the following are the reasons why you should choose our color sorter.

Technical advantages

This e-waste recycling device uses advanced photoelectric sensing technology, which can not only detect the color information of materials with high precision but also achieve accurate sorting. At the same time, our color sorters are very responsive. Therefore, its efficiency is high and it can handle a large number of materials.

Reliability and stability

Our color sorters use high-quality materials and components, undergo strict quality control and testing, and have good durability and stability. Moreover, it can operate stably for a long time. Thus, it reduce the time and cost of downtime and maintenance.

Flexibility and customizability

Our color sorters can not only be customized and adjusted according to the needs of customers to adapt to different materials and sorting requirements. Moreover, the sorting parameters can be flexibly set to achieve diversified sorting effects.

Cost-effectiveness

Despite the cost advantages of our equipment, such as low maintenance costs, low energy consumption, and long-term economic benefits for customers, our equipment is still reasonably priced.