The double-shaft shredder is a device that processes various solid wastes, which is very important for waste sorting, recycling, and environmental protection. It can process a variety of materials such as plastics and metals, which helps to reduce pollution. Valuable products such as recycled plastics can also be produced from shredded waste, promoting resource recycling. In addition, it can effectively reduce the volume of waste and save space. At the same time, its efficient processing capacity can also improve production efficiency. Therefore, the double-shaft shredder plays an indispensable role in waste treatment, environmental protection, resource recycling, and other aspects.

What are the working principles and unique advantages of the double-shaft shredder?

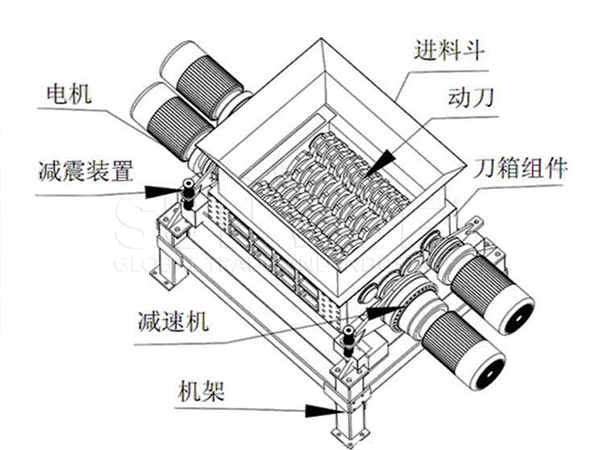

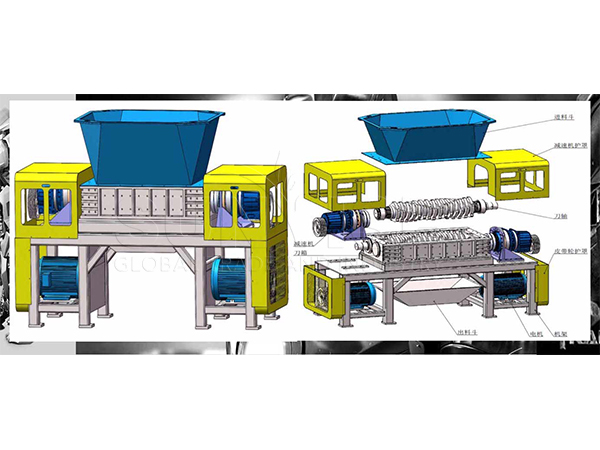

The working principle of the double-shaft shredder is mainly to shred materials through two sets of counter-rotating blade shafts. After the materials enter the shredder, the combined effects of shear force, tearing force, and extrusion force generated by the two sets of blade shafts will shred them. There are no grids or sieve holes between the double-shaft shredders, so no matter what the size and shape of the materials are, they can be effectively shredded.

The unique advantages of the double-shaft shredder are mainly as follows.

How to choose a double shaft shredder that suits your needs?

What is the price of a double-shaft shredder?

Several factors, such as brand, specifications, and materials, influence the price of double-shaft shredders in the market.

First of all, the price of a double-shaft shredder is closely related to the brand. Well-known brands tend to offer relatively high prices, but they also bring reliable quality and high-quality after-sales service. For example, brands such as Siemens and Schneider, their prices are about $8,000-16,000. In contrast, some unknown brands or low-end brands of double-shaft shredders may be relatively low-priced, and their prices are between $3,000 and $6,000. However, there is a certain degree of uncertainty in quality and performance. You need to choose the corresponding brand according to your needs and budget.

Secondly, the price of a double-shaft shredder is also closely related to specifications and functions. There are differences in power, processing capacity, noise, etc. provided by double-shaft shredders of different specifications, so the prices will also be different. Generally speaking, higher-specification double-shaft shredders are relatively expensive and are suitable for processing large quantities and harder materials, such as the model YS-500, which costs about $7,000; while lower-specification double-shaft shredders are relatively cheap and are suitable for processing small batches and relatively soft materials. For example, the model is YS-300, and its US dollar is about 3,000 US dollars.

Last but not least, the price of the double-shaft shredder is also related to the material. Some high-end double-shaft shredders are made of wear-resistant alloy steel. Because of its high strength and wear resistance, the price is relatively high. The general price is 8,000-13,000 US dollars; while some low-end double-shaft shredders may be made of general carbon steel, which is relatively low in price. The general price is 4,000-7,000 US dollars. You can choose the appropriate material according to the actual use environment and the characteristics of the processed materials.