Eddy current sorter is a separator for separating and classifying solid particles. In short, its role is to separate and screen the particles in the mixture according to their density, shape and size characteristics, so as to achieve the recovery, purification or classification of the material. More importantly, the eddy current separator can realize the recycling of waste and improve the utilization rate of resources. It can be seen that it helps to reduce waste discharge and environmental pollution, achieve effective resource utilization and environmental protection, and therefore conforms to the principle of sustainable development.

Which processes can use eddy current separators?

You can utilize the eddy current sorting machine in a variety of processes, especially for separating and classifying solid particles.I will introduce you below.

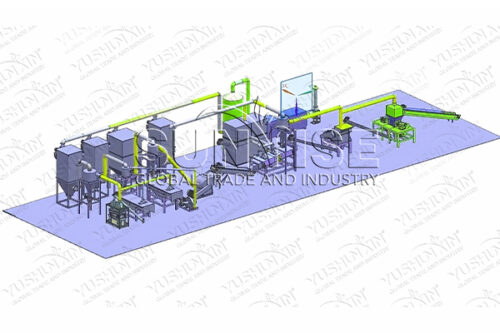

Waste treatment

As mentioned earlier, during the waste treatment process, you can use eddy current sorters to separate solid waste and recycle it. For example, it can use eddy current sorters in waste treatment processes to classify scrap metal, plastic, glass and other materials for reuse or recycling.

Ore processing

At the same time, eddy current sorters can purify and sort the ore by utilizing differences in the physical and chemical properties of the ores, allowing eddy current separators to separate useful minerals from waste rock. As a result, this process improves the quality and value of the ore.

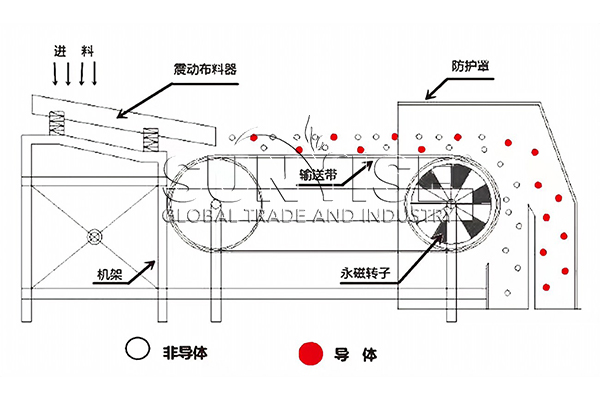

Metal recycling

In particular, you can use eddy current separators for sorting metal and sorting in metal recovery processes. Because vortex separators utilize the electrical and magnetic properties of different metals, they can separate out the mixed metals for recycling.

Powder processing

Generally, eddy current sorters can be used for the separation and classification of powder particles. In summary, vortex separators separate and screen particles of different size and composition by taking advantage of characteristics such as particle size, density and shape.

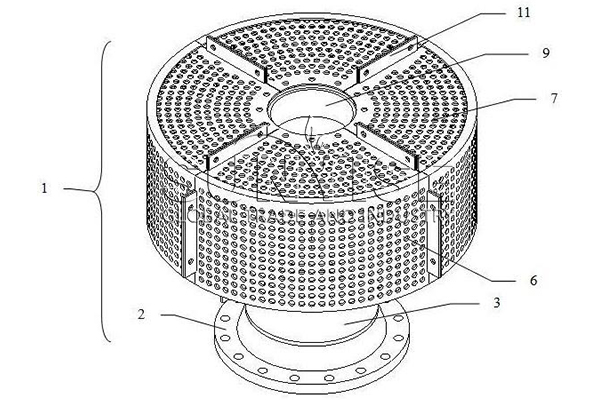

Working principle of eddy current separator.

At present, the eddy current separator is a device that uses the principle of separation of particles in a fluid by centrifugal force. Here’s how it works.

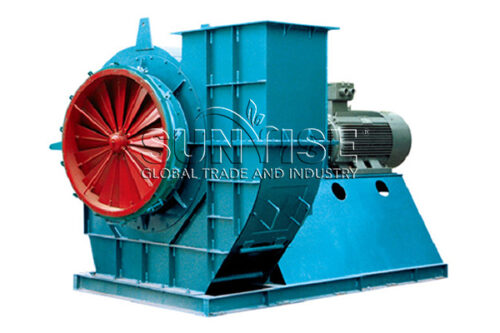

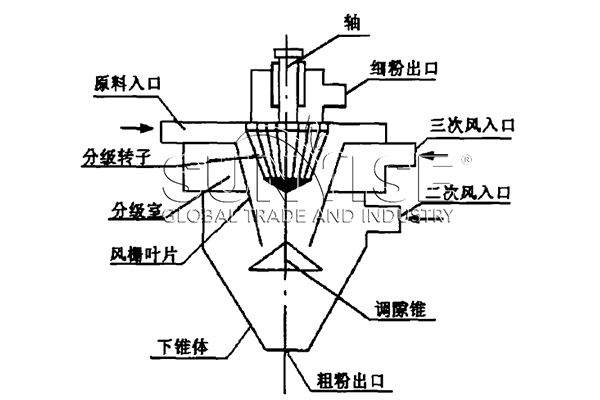

Air flow generation

Currently, vortex separators generate high velocity air flow through an air generator. Specifically, the airflow generator is usually a rotating impeller or cyclone. Then, when the airflow generator rotates, a strong centrifugal force is created, so air can be brought into the sorting chamber.

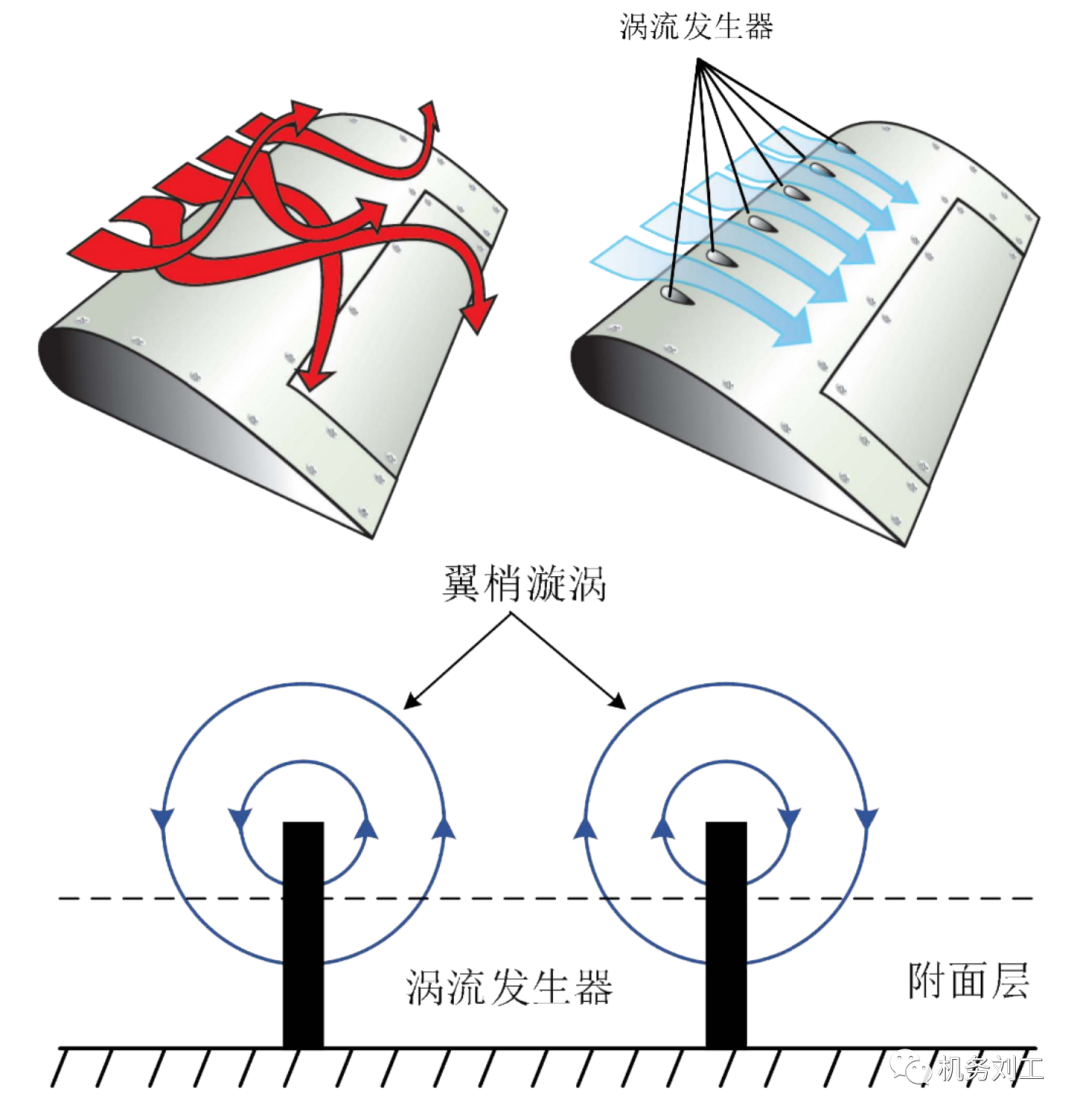

Vortex formation

There is no doubt that the air entering the sorting room will create a swirling vortex in the sorting room. And when a fluid rotates, it creates fluid vortices. The vortex therefore has a high velocity and centrifugal force, so it can separate and aggregate particles in different regions.

Particle separation

The centrifugal force in the vortex affects particles entering the vortex separator. Thus,the centrifugal force separates particles into different locations in the vortex. The vortex throws heavier particles to the outside, while it brings lighter particles to the central part. In this way, the system separates the particles into different regions based on their mass and shape.

Sorting and classification

Similarly, different discharge ports can be set according to the requirements of the particles. Plus, other devices can also be used for sorting and sorting. Therefore, the heavier particles are collected through the discharge port, and the lighter particles are discharged or continue to be processed.

If you are interested in us or have other questions, please contact us.