Activated carbon is a very fine carbon particle with a large surface area, and there are even finer holes in the carbon particles – capillaries. In addition, this capillary has a strong adsorption capacity. Since the surface area of the carbon particles is large, they can fully come into contact with the gas (impurities). The most important thing is that when these gases (impurities) touch the capillaries, they are adsorbed and play a purification role. Finally, the essence of activated carbon adsorption is to use the characteristics of activated carbon adsorption to adsorb organic solvents in low-concentration and high-volume exhaust gas into activated carbon. Therefore, the activated carbon adsorption method is mainly used to remove low-concentration gaseous pollutants.

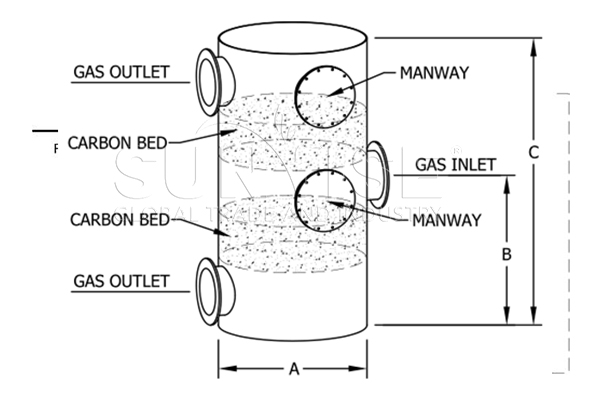

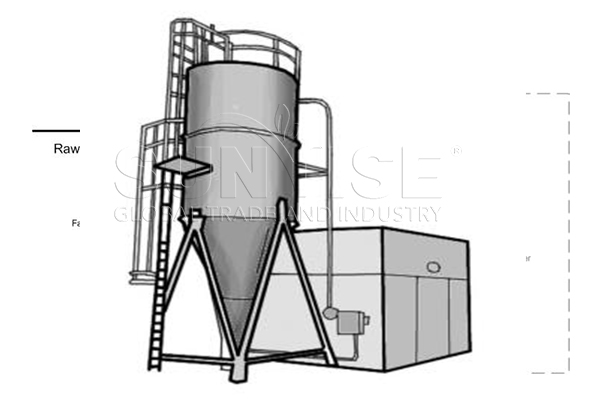

4 major structures of activated carbon adsorption equipment.

What are the uses of activated carbon adsorption box?

Activated carbon adsorption box is mainly used for the treatment of large air volume and low concentration of organic waste gas. In addition, activated carbon adsorbent can treat and purify a variety of organic and inorganic pollutants. For example, benzene, ketones, alcohols, ethers, alkanes and their mixed organic waste gas, acidic waste gas, alkaline waste gas. Most importantly, you can use this equipment in the purification of harmful waste gas generated in pharmaceutical, smelting, chemical, machinery, electronics, electrical appliances, coating, shoemaking, rubber, plastics, printing and environmental protection desulfurization, deodorization and various industrial production workshops.

Which e-waste recycling processes use activated carbon adsorption equipment?

There are many e-waste recycling processes that require activated carbon adsorption equipment. Below I will introduce 2 of them in detail.

Pyrolysis process

Pyrolysis of electronic waste will generate various volatile organic compounds and complex compounds. You can use activated carbon adsorption equipment to effectively capture and remove these harmful components. For example, the process of recycling photovoltaic panels into cracking furnaces.

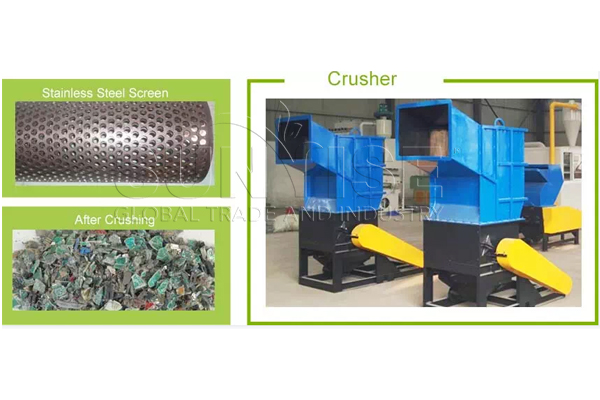

Crushing process

During the disassembly and crushing of electronic components, waste gas containing harmful gases such as sulfur dioxide and hydrogen chloride may be generated. You can use activated carbon adsorption equipment to adsorb and remove these harmful gases. For example, crushing circuit boards, lithium batteries, etc.

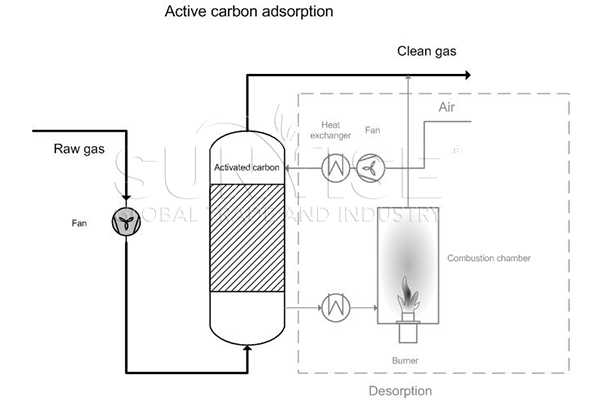

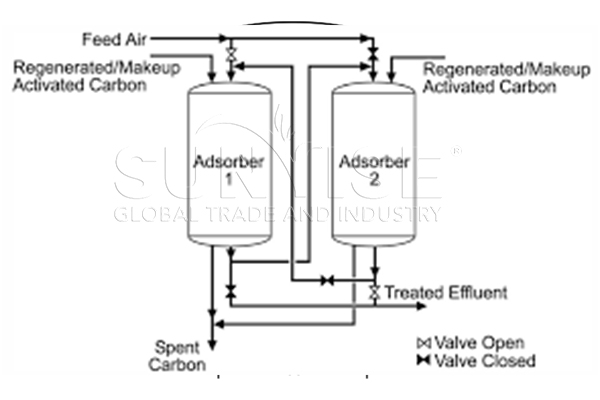

How does the activated carbon adsorption equipment you use work?

First, when the exhaust gas enters the adsorption box powered by the fan, the exhaust gas enters the activated carbon adsorption layer. Due to the unbalanced and unsaturated molecular attraction on the surface of the activated carbon, it can attract the exhaust gas molecules to gather on the surface. This phenomenon is called adsorption. Finally, using the adsorption capacity of activated carbon, the pollutants in the exhaust gas are adsorbed on its surface, and the purified gas is finally discharged into the air.

What is the price of activated carbon adsorption equipment?

The price of activated carbon adsorption equipment is affected by many factors, including equipment specifications, production capacity, materials used, and brand.

Capacity

If you need to treat a large amount of waste gas or wastewater, such as hundreds of thousands of cubic meters per hour, you will need to spend about $12,000 to choose our YS-800 equipment. If you have a small industrial workshop and only need to treat a few to tens of cubic meters per hour, you will only need about $5,000.

Type and quality of activated carbon

If you need to treat specific pollutants (such as volatile organic compounds, heavy metals, acidic gases, etc.), the price will be higher, about $15,000. Because these activated carbons are usually specially treated to more effectively adsorb specific pollutants. On the contrary, if you do not have special requirements, the price of the equipment is very cheap, about $4,000. Because activated carbon is widely available and inexpensive.

Equipment material

This needs to be selected according to your actual situation. For example, carbon steel is relatively cheap and suitable for general environments. However, it is easy to rust in a humid or corrosive gas environment and requires regular maintenance and coating protection. If you don’t care about this shortcoming, its price is about $6,000. If you have requirements for the applicable environment of the equipment, it is recommended that you choose stainless steel, which has good corrosion resistance. The price is about $1,000 to $15,000.

4 major advantages of our company’s activated carbon adsorption equipment.

- 1

High adsorption efficiency, strong capacity and fully enclosed type, can be used indoors and outdoors.

- 2

Able to treat multiple mixed organic waste gases at the same time; purification efficiency ≥ 95%.

- 3

The equipment has a compact structure, small footprint, simple maintenance and management, and low operating costs.

- 4

It adopts automated control operation design, which is easy and safe to operate.