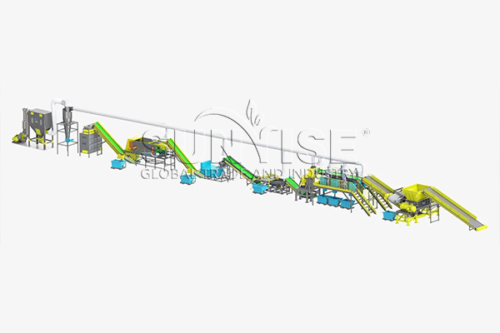

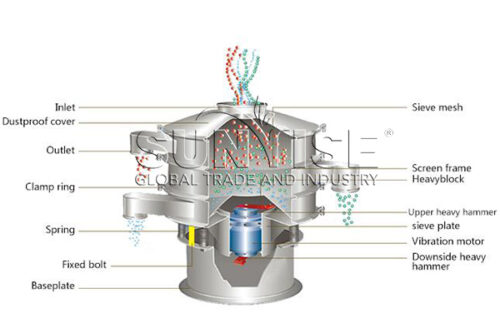

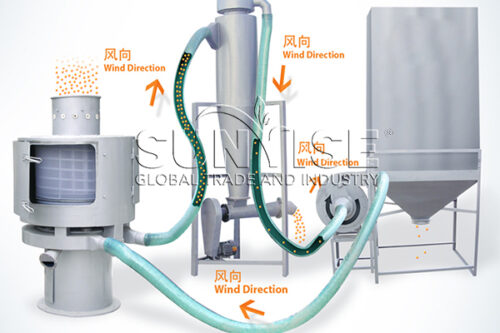

Vibrating screen separator is a commonly used equipment for separating and screening solid particle materials, which has a wide range of applications. Its function is to separate materials of different particle sizes through the vibration force and screening effect of the screen, so as to achieve the purpose of screening and grading. It has a wide range of applications in industrial production, which can not only improve production efficiency, reduce costs, but also improve product quality.

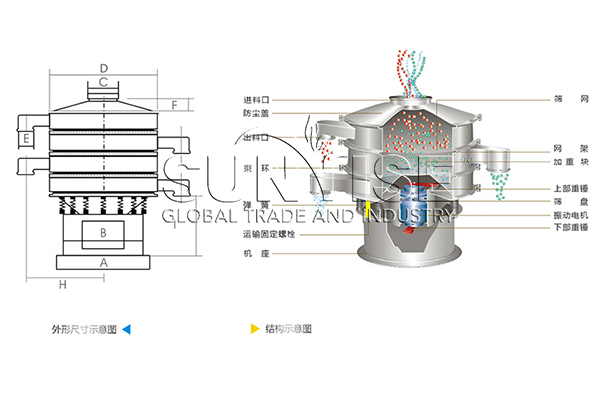

What structures does the vibrating screen separator include?

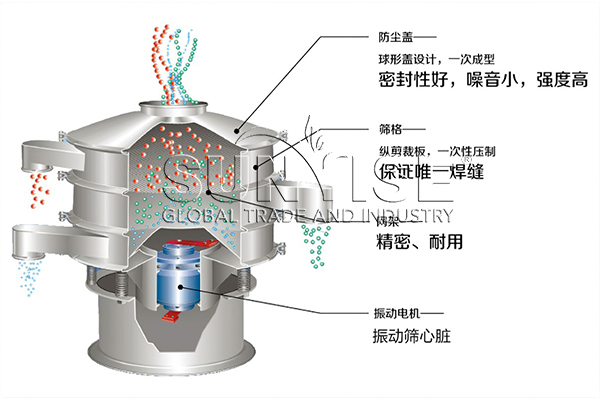

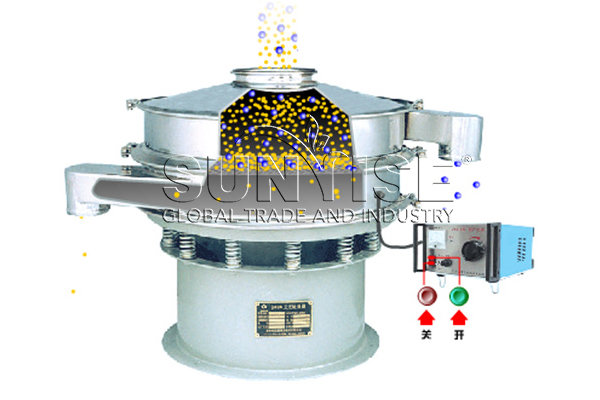

The vibrating screen separator mainly includes the following main structures.

What materials are vibrating screen separators suitable for?

Vibrating screen separators are suitable for many different types of materials, including but not limited to the following.

Can the vibro sieve separator achieve the required particle size classification, that is, what is the screening accuracy?

According to different models and specifications, the screening accuracy of the vibrating screen separator will be different. In general, the vibrating screen separator can achieve a high screening accuracy, so it can meet the size classification requirements of most materials.

The screening accuracy of the vibro sieve separator depends on the following factors.

Screen specifications

Vibrating screen separator adopts different sizes of screen. Therefore, it can achieve different screening accuracy. In addition, the aperture and shape of the screen will greatly affect the particle size range through which the material passes.

Vibration frequency and amplitude

The vibration frequency and amplitude of the vibrating screen separator will affect the movement of the material on the screen. Therefore, it can affect the screening accuracy. Generally speaking, higher vibration frequencies and appropriate amplitudes can improve screening efficiency and accuracy.

Material characteristics

Different materials have different characteristics, such as particle shape, humidity, viscosity, etc. In addition, these characteristics will also affect the screening accuracy of the vibrating screen separator.

Is the operation of the vibrating screen simple and easy to learn? Does it require training to operate?

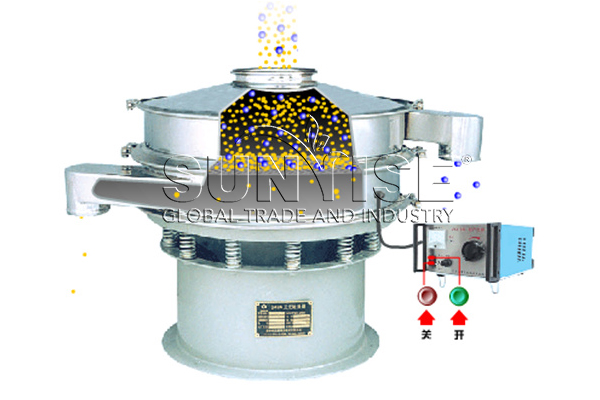

The operation of our vibrating screen separator is usually relatively easy to learn and does not require much training to perform basic operations.

In general, the operator only needs to understand the basic principle and function of the machine, learn to start and stop the machine, adjust the basic parameters such as vibration intensity and vibration frequency. In addition, some advanced features or special operations may require some additional training or guidance. However, depending on different shaker models and brands, the specific situation may be different. So you can consult our relevant training and technical support before purchasing.