E-waste recycling plant cost is an important topic because it is directly related to the feasibility and effectiveness of waste recycling. Moreover, the cost structure and influencing factors of e-waste recycling plants are diverse. An e-waste recycling plant cost includes equipment purchase costs, operating costs, labor costs, and environmental protection investment. The e-waste recycling plant cost will also be affected by factors such as regional differences, policy environment, and market demand. Understanding e-waste recycling plant cost can help make sound policy and business decisions to promote sustainable development of e-waste recycling. However, as long as you choose our company, we will meet your various needs. Because we can offer you a variety of solutions and customized services.

What are the factors that affect the price of e-waste recycling?

The cost of recycling different types of e-waste is affected by several main factors.

Recycling scale

The size of the recycling scale will also have an impact on costs. Large-scale recycling projects typically require more equipment and workers, as well as more space and higher energy consumption. This adds to the cost.

How much does it cost to build a factory for e-waste?

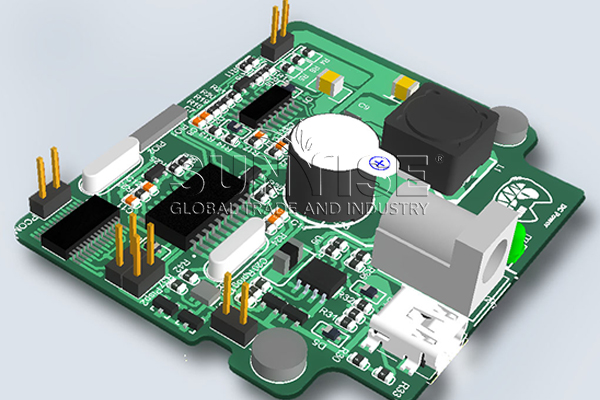

If you want to know an e waste recycling plant cost, you should first understand the cost of e-waste recycling. The cost of e-waste recycling is primarily determined by the price of the equipment. The type of equipment you choose depends on the specific e-waste materials being processed and the need for output volume.

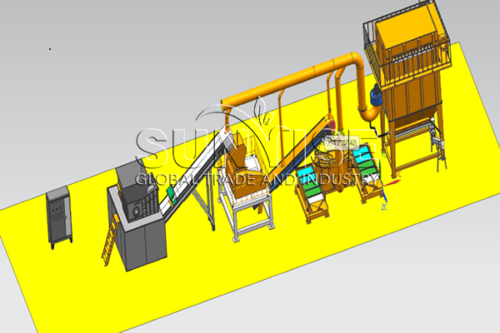

For example, the recycling of photovoltaic panels involves framing machine, cracking furnaces, dust removal equipment, color sorters, screening equipment, etc. If you want to use these to build an electronic waste recycling plant, the cost will be between$90,000 and $130,000. For lithium battery recycling, it involves crushers, screening machines and dust removal equipment.If you are planning to establish an electronic waste recycling plant, the estimated cost would range from $150,000 to $180,000. This amount includes the expenses for purchasing necessary equipment and setting up the facility.

To segment further, you need to provide the required output.

According to your needs, we will give you specific and appropriate solutions. This will give you an idea of the cost of the equipment and the e-waste recycling plant.Therefore, before considering the cost of an e-waste recycling plant, you need to first consider the cost of the equipment. What equipment to choose? This will depend on the specific type of e-waste you are dealing with and your production needs.

What are the different costs of setting up e-waste recycling plants of different sizes?

The different sizes of e waste recycling plant cost is also very different, and the equipment required is also slightly different.

The cost of setting up small e-waste recycling plant.

If you plan to build a small electronic waste recycling plant with a production capacity of 0.4t/h~0.5t/h, you can choose equipment configurations. For instance, options include a PCB disassembly machine, PCB crusher machine, circuit board crusher, high-voltage electrostatic separation device, gravity sorting equipment, and pulse dust collector.For the choice of these devices, you can choose a device with model number YS-500. It has less weight and power. Therefore, energy consumption can be reduced and costs can be reduced. The cost of setting up a small e-waste recycling plant will also be relatively low, ranging from approximately $11,400 to $55,960.

The cost of setting up a medium-sized e-waste recycling plant.

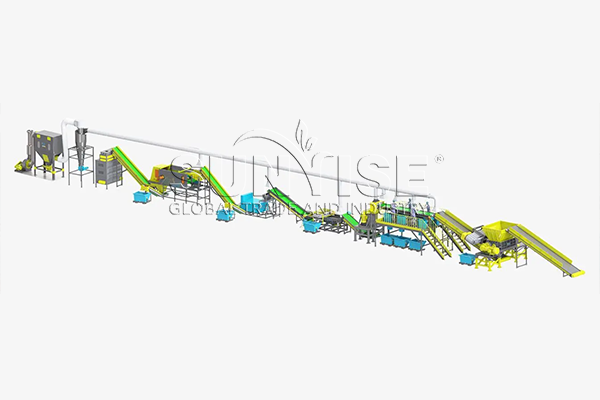

If you plan to build a medium-sized e-waste recycling plant, you will need to configure the following equipment. Such as a dual-shaft shredder, hammer crusher and crusher. In addition, air flow screen and high voltage electrostatic separation device and other equipment.Additionally, pulse dust removal equipment should be included in the setup. The example used for this configuration is the recycling of waste circuit boards (PCBs).For the selection of these equipment, you can choose the equipment model YS-800. The construction cost of a medium-sized e-waste recycling plant is slightly higher than that of a small recycling plant, ranging from approximately $50,000 to $89,000.

The cost of setting up a large e-waste recycling plant.

If you are considering building a large e-waste recycling plant, specifically for the recycling of used circuit boards (PCBS). Then you need to be equipped with a dual-shaft crusher, circuit board crusher. And analysis machine, pulse purifier, vibrating screen separator and specific gravity separator. These components will play vital roles in the effective recycling of e- waste materials.In addition to these essential machines, high-voltage electrostatic separation equipment and other necessary machinery should also be considered in the equipment selection process.For the selection of these equipment, you can choose the equipment model YS-1000. Large-scale e-waste recycling plants have the highest construction costs, ranging from approximately $90,000 to $155,000. However, correspondingly, it also yields the highest profits.

Minimal cost to set up an e-waste recycling plant.

If you have special needs regarding cost, we can also provide customized services to try our best to meet your needs. Additionally, we can tailor the equipment configuration and solutions for your e-waste recycling plant based on your specific requirements and budget. Whether it is a small, medium or large recycling plant, we can choose the right equipment for your needs. More importantly, offer the price accordingly.Our aim is to offer you cost-effective and dependable recycling solutions that are both efficient and environmentally friendly. These solutions will help you meet your objectives of environmental protection and resource recovery.No matter the size of your project, we will wholeheartedly provide you with professional technical support and after-sales service. Please feel free to contact us. We look forward to working with you to advance the development of e-waste recycling.