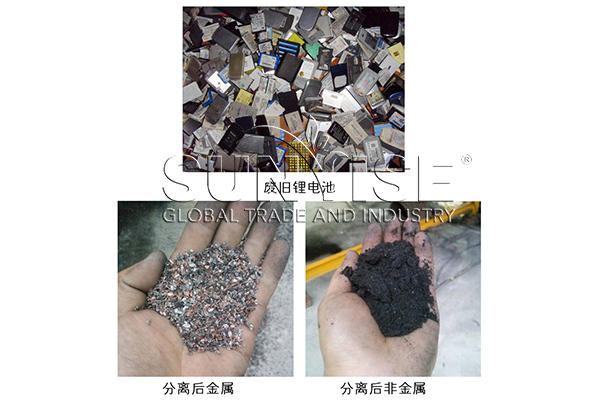

With the rapid development of electric vehicles and renewable energy, the recycling of waste lithium-ion batteries has become increasingly prominent. And graphite is one of the important materials for lithium-ion batteries. However, recycling graphite from used lithium-ion batteries faces many challenges, including equipment and technology costs, labor costs, waste disposal costs, and environmental and safety costs. In addition, although the recycling of graphite has a certain cost, it also brings opportunities for environmental protection and resource utilization. Therefore, the research and development of waste lithium-ion battery graphite recovery technology is helpful to promote the development of green circular economy and realize the sustainable use of resources.

What are the challenges in graphite recycling from spnet lithium ion batteries?

Graphite recycling from spent lithium ion batteries presents the following challenges.

Complex recycling process

The internal structure of waste lithium-ion batteries is complex and contains a variety of materials. Therefore, the recovery of graphite requires a variety of processes and technical treatment.

High technical difficulty

In used batteries, it is difficult to separate effectively because graphite is mixed with other materials. Therefore, efficient separation techniques and equipment are required.

High recycling costs

Due to the high cost of existing graphite recovery technology. Such as equipment investment, labor costs and so on. So reducing recovery costs is a challenge.

Risks of environmental pollution

Because the recycling of waste lithium-ion batteries may produce harmful waste or wastewater, there is a risk of environmental pollution. So you need to take effective measures to deal with and reduce pollution.

Difficulties in resource reuse

Recycled graphite may contain impurities or be of poor quality. Therefore, how to effectively reuse the recycled graphite is also a challenge.

Legal and regulatory restrictions

Because the recycling of waste batteries involves environmental protection, resource utilization and other laws and regulations. So you need to comply with regulations, which increases the complexity and cost of recycling.

How to recover graphite from spent lithium ion batteries to reduce recycling costs?

To reduce the cost of graphite recovering from spent lithium ion batteries, you can take the following steps.

Improve recycling efficiency

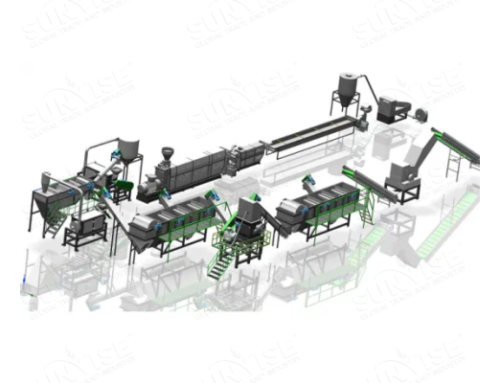

Use efficient separation technology and equipment to increase the recovery rate of graphite and reduce resource waste.

Reduce energy consumption

Optimize the recycling process and then reduce energy consumption. For example, the use of low energy separation methods or equipment.

Reduce labor costs

The introduction of automated production lines. Only in this way you can reduce manual operations., thus reducing labor costs.

Increase the scale of recycling

Scale up recycling. In addition, economies of scale are used to reduce production costs.

There are three things that are easy to overlook that can also reduce costs.

Recycle equipment and materials

Recycle equipment and materials as much as possible to reduce raw material procurement costs.

Expand resource channels

Seek partners or recycling channels. Therefore, more high-quality raw materials can be obtained and production costs can be reduced.

R&D and innovative technology

Continue to carry out research and development innovation. This is in order to develop efficient and low-cost recycling technologies and equipment.

Leave A Comment