First of all, remember that aluminum recyclers are equipment used to recover and reuse waste aluminum. Therefore, its role is to treat waste aluminum materials. Only in this way can contaminants be removed, thus returning it to a reusable state. In addition, there is no doubt that waste aluminum, if handled improperly, may cause environmental pollution. In addition, aluminum recycling machines can recover and reuse waste aluminum materials into new aluminum products. This therefore helps to conserve resources and reduce the need for raw materials. In summary, the importance of aluminum recyclers is reflected in resource reuse, energy conservation and emission reduction, as well as economic benefits and waste treatment.

2 major crushing equipment in aluminium recycling.

These two aluminum recycling machines are the main crushing equipment of our company. Their working principles are as follows.

Based on its internal blade system and rotating shaft, this aluminum recycling machine cuts, tears and squeezes waste or solid materials into smaller particles or filaments through high-speed rotating blades. The clever arrangement and movement of the blades create powerful tearing and cutting forces, allowing waste to be broken down and processed efficiently.

Crusher

Mainly crushes materials into smaller particles through impact, collision and crushing. The crusher usually puts the materials into the crushing cavity through the relative movement of the rotor and the stator, and then impacts and crushes the materials through the high-speed rotating blade or hammer.

2 major screening equipment and detailed introduction.

These aluminum recycling machines play a role in separating impurities, non-metallic substances and classifying and screening during the aluminum recycling process, improving the recycling efficiency and purity of aluminum materials.

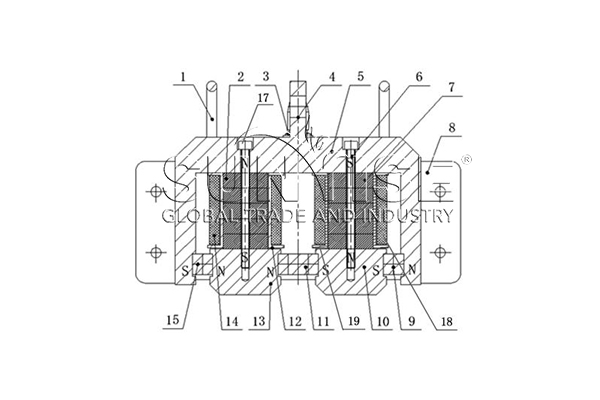

Magnetic sorting machine

By adjusting the magnetic field, magnetic separator, etc.,different magnetic substances can be sorted to purify ores or recover useful minerals.

Eddy current sorting machine

The eddy current separator uses a rotating magnetic field to generate an eddy current effect, which separates conductive materials and non-conductive materials in the eddy current separator.

How to reduce pollution during aluminum recycling?

Pollution can be effectively reduced by using our two major aluminum recycling machines. Here is how they work.

Spray tower

The nozzle sprays the spray over the gas, causing the pollutants in the gas to contact and react with the liquid, thereby separating the gas and liquid.

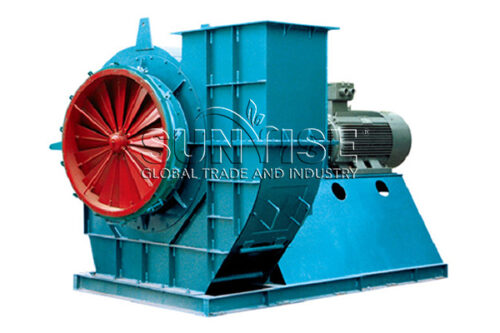

Pulse dust collector

Utilize the pores and fiber structure of the filter material to filter and remove dust from the air.

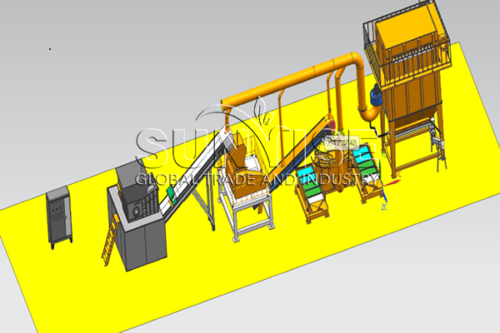

How can aluminium be recycled?

The process of recycling aluminum through our aluminum recycling machine is as follows.

Why choose our aluminum recycling machine?

These are just some of the many advantages of our aluminum recycling machines. I summarize them below for you. Choosing our aluminum recycling machines will be the right decision for you.

Efficient performance

Our aluminum recycling machines have efficient recycling capabilities and can quickly process large amounts of scrap aluminum materials. It uses advanced technology and design to effectively separate and recycle aluminum, improving recycling efficiency and production capacity.

High-quality recycled products

Our aluminum recycling machines can effectively classify and process scrap aluminum to ensure that the quality of recycled aluminum products meets standard requirements. This means that recycled aluminum can be used directly in recycled manufacturing without the need for additional processing and purification.

Environmental performance

Our aluminum recycling machine has excellent environmental performance. It uses advanced technology and processes to effectively process scrap aluminum and reduce resource waste and environmental pollution. At the same time, it also complies with relevant environmental protection regulations and standards and can provide your company with green and environmentally friendly recycling solutions.

Reliability and Durability

We carefully design and manufacture our aluminum recyclers for superior reliability and durability. It uses high-quality materials and components. Therefore, it can maintain stable and efficient performance for a long time. This reduces maintenance and replacement costs.

Customization and service support

We can customize an aluminum recycling machine for your business based on your specific needs, ensuring that it meets all of your requirements.

What is the most important thing about recycling aluminum?

The most important thing for recycling aluminum is efficient collection and sorting.

Effective collection

First of all, ensure that the waste aluminum is collected in a timely manner, so that it can prevent it from being randomly discarded or mixed with other garbage. At the same time, it also requires the establishment of a complete recycling network and mechanism. This also includes setting up recycling sites. In addition, convenient recycling containers and bags can be provided. Therefore, it is convenient for residents and enterprises to put the waste aluminum into the recycling system.

Classification

Secondly, the classification of waste aluminum is a prerequisite for recycling. Because different types of aluminum products require different recycling methods and processes. For example, aluminum cans, aluminum foil and scrap aluminum products. In contrast, accurate sorting can improve recycling efficiency. Therefore, it not only reduces the recovery cost, but also ensures that the quality of recycled aluminum meets the standard requirements.

Why should we recycle aluminum?

Because recycling aluminum through aluminum recycling machines has a positive impact on resource conservation, energy conservation, environmental protection and economic development, it is a sustainable development measure.

Save resources

Recycling aluminum in the first place can reduce the demand for aluminum ore, thereby avoiding over-exploitation of natural resources. In addition, it can also extend the service life of aluminum through recycling, thus making it a renewable resource.

Energy saving

Secondly, while it takes a lot of energy to produce aluminum products, recycling only takes about 5 to 10 percent of that energy. Compared with the process of extracting aluminum from ore, the energy consumption is greatly reduced.

Reduce pollution

In third place, due to the production process of aluminum will produce a lot of waste gas, wastewater and solid waste. And they contain substances such as harmful substances and heavy metals. Therefore, recycling aluminum can reduce environmental pollution and damage to the ecosystem.

Reduced greenhouse gas emissions

Finally, the production process of aluminum is energy intensive. Therefore, reducing aluminum production can reduce greenhouse gas emissions and thus mitigate climate change.