The circular vibrating screen plays a vital role in the production process. Because the screening and separation of materials are inseparable from it, especially in the production of silicon. The use of a circular vibrating screen can effectively separate the silicon from other materials to obtain pure silicon. This is therefore particularly important when making solar panels or other products that require the use of silicon. In addition, the compact design of the circular shaker saves space and improves production efficiency. Whether in terms of quality control, product purity, or production efficiency, the circular vibrating screen plays an important role.

What is the structure of the circular vibrating screen?

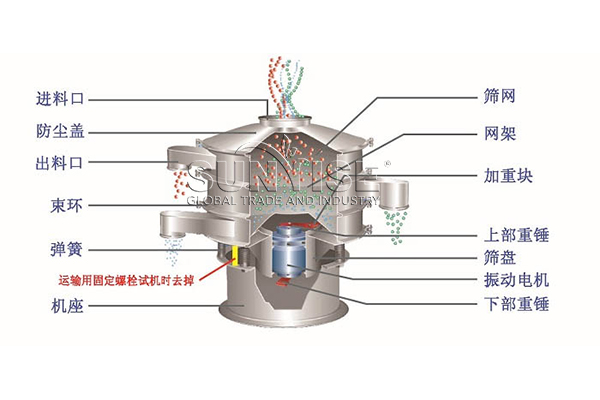

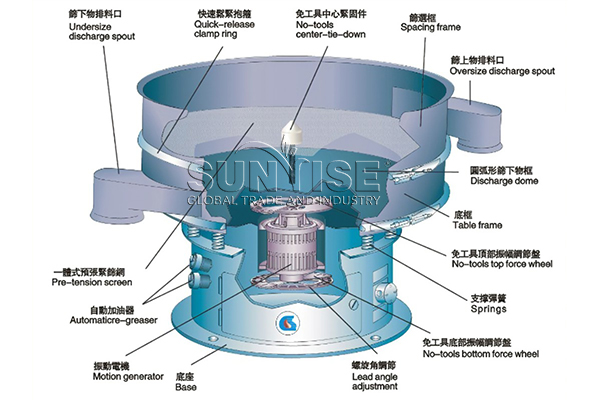

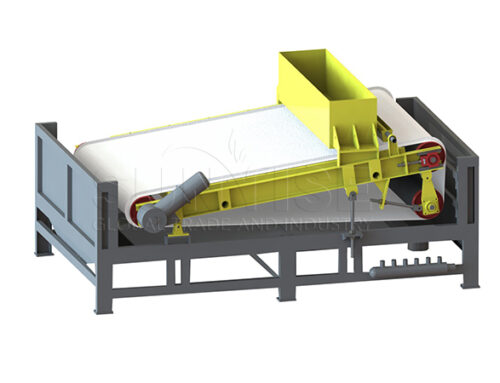

The screen machine mainly comprises a screen box, screen mesh, vibrator, damping spring device, bottom frame, and so on. Therefore, you can adjust the amplitude using cylindrical eccentric shaft exciters and deflectors. In addition, the motor and the triangle belt drive it, and motor and the triangle belt drive it, and someone installs it on the side plate of the screen box. This rotation can produce centrifugal inertia force, which forces the sieve box to vibrate.

How does the circular shaker work?

The motion trajectory of the circular vibrating screen box is circular or oval. Because the circular vibrating screen uses an inertia shaker to generate vibration, the vibration source is generally a motor-driven shaker. In addition, the circular vibrating screen is a single-axis exciter, someone fixes the main shaft on the screen box and the motor drives it to rotate at a certain speed. At the same time, the eccentric body that is installed on the main shaft also rotates and produces a centrifugal inertia force., so that the screen box vibrates freely, producing an approximate circular vibration track.

What are the advantages of our round shakers?

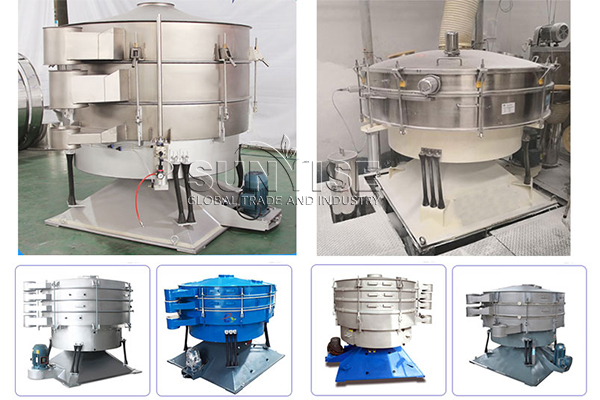

Circular vibrating screen Circular vibrating screen is a kind of circular vibration, multi-layer, new vibrating screen. Our company has applied a variety of screening auxiliary configurations to better understand the personalized screening needs of customers. This approach meets the needs of different industries and achieves the purpose of screening. With advanced performance, the equipment is widely used in the product classification of mining, building materials, transportation, energy, chemical and other industries.

Is there any difference between YK series circular vibrating screen and YKR series circular vibrating screen?

YKR series round vibrating screen is in Germany KHD company’s USK type vibrating screen based on the summary of China’s many years of research, design, production, and use of screen experience, combined with China’s national conditions and developed a new series of vibrating screen, is USK type vibration innovation, domestic products, can replace the USK type vibrating screen and other existing series of screen. It is widely used in coal, power, mining, building materials, chemical and other industries.

YK series circular vibrating screen is an efficient vibrating screen manufactured by absorbing German technology. You can use this method to screen sand and stone in quarries and classify products in coal preparation, mineral processing, building materials, electric power, and chemical industries.

What is the price of circular vibrating screen?

The price of circular vibrating screen is affected by a variety of factors, and I will give you an example below.

Performance factor

Several factors affect the price of the circular vibrating screens, including screening efficiency, production process, material selection, and others. For example, the circular vibrating screen made of polymer materials is priced around $6000-10,000. This is because it is lightweight, has good wear resistance, and has high chemical stability. The steel round shaker only costs about $5,000. The screening efficiency of different specifications of circular vibrating screens will vary, and the higher the screening efficiency of the equipment is often relatively high. For example, the model YS-800 circular vibrating screen has a production efficiency of 5000kg per hour and needs about $7,000. But the round shaker of the YS-500 costs only about $5,000. In addition, the complexity of the production process and the choice of materials also directly affect the price of equipment.

Brand factor

In addition, there are certain price differences between different suppliers and brands. Some well-known brands of circular vibrating screens usually relatively high prices. For example, the price of Siemens brand’s circular vibrating screen is about $9,000 – $12,000. This is due to its brand effect and quality assurance. However, some ordinary brands or small manufacturers of circular vibrating screen prices may be relatively low, but the quality and after-sales service reliability will also be reduced.

How about our after-sales service?

Our after-sales service is professional and efficient as the core. We take customer satisfaction as the ultimate goal, not only the pursuit of product quality and performance, but also pay more attention to providing customers with quality after-sales service, so that customers can enjoy a better shopping and use experience. We warmly welcome you to contact our after-sales service team at any time to feel our dedication and professionalism!

Leave A Comment