get started quickly with…

manage accounts

business insights

download guides

how to grow your business online – videos help

Cuisque cursus metus vitae sedpharetra auctor interdum magna auge get diam mas vestibulum anipsum faucibus ipsum.

how to easily generate successful business ideas

business registration platforms for a streamlined process

frequently asked questions

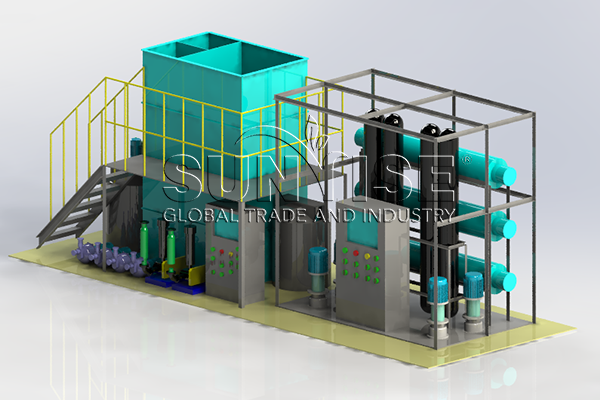

As the demand for lithium batteries rises, so does the need for effective recycling solutions. Understanding the price of a lithium battery recycling line is crucial for businesses considering this investment. Let’s delve into the various factors that influence the cost and explore specific pricing and equipment configurations based on different production capacities.

What Factors Determine the Price of a Lithium Battery Recycling Line?

Three primary factors influence the price of a lithium battery recycling line: capacity, equipment, and configuration.

The capacity of a recycling line significantly impacts its price. A line designed to handle 200-300 kg/h will have a different cost compared to one with a 300-500 kg/h capacity. Higher capacity generally means a higher price due to the need for more robust and efficient machinery.

The type and quality of equipment used in the recycling line also affect the overall cost. Essential components like shredders, separators, and purification systems come in various types and efficiencies. Higher-end equipment with advanced features and durability will naturally be more expensive.

The configuration of the recycling line, including automation levels and additional features, further influences the price. Fully automated systems with sophisticated monitoring and control features will cost more than semi-automated or manual systems. The choice between these configurations depends on the specific needs and scale of the operation.

How Much Does a Lithium Battery Recycling Line Cost?

The price of a lithium battery recycling line can range from $5,000 to $21,000. This wide range reflects different capacities and equipment configurations.

For a recycling line with a capacity of 200-300 kg/h, the price generally falls between about $5,000 to $11,500. This setup typically includes:

Shredder: For initial size reduction of the batteries.

Separator: To segregate different materials such as metals and plastics.

Purification System: To refine and purify the recovered materials.

This configuration suits small to medium operations, offering a balance of efficiency and cost.

A recycling line designed for 300-500 kg/h capacity ranges from approximately $11,500 to $21,000. This setup often includes:

High-Capacity Shredder: Capable of handling larger volumes of batteries.

Advanced Separation Technology: For higher efficiency in material segregation.

Comprehensive Purification System: Ensuring high purity of recovered materials.

Automated Control Systems: For enhanced process monitoring and control.

This configuration is ideal for larger operations requiring high throughput and efficiency.

In conclusion, the price of a lithium battery recycling line depends on capacity, equipment, and configuration. For small to medium operations, a 200-300 kg/h line costs between $5,000 and $11,500. Larger-scale operations may opt for a 300-500 kg/h line priced between $11,500 and $21,000. Understanding these factors helps businesses make informed decisions, investing in the right recycling line to meet their needs. This not only contributes to environmental sustainability but also offers economic benefits. If you want to know 1000kg/h lithium battery disposal, you can also contact us.

Lithium-ion battery recycling machinery recycles waste batteries through pretreatment, crushing, sorting, and chemical treatment. In addition, these machines help separate and extract valuable metals such as lithium, cobalt, and nickel from batteries, reduce resource mining, and improve resource utilization. More importantly, recycling not only reduces environmental pollution but also has economic benefits. If you are interested in lithium-ion battery recycling machinery, the choice of lithium-ion battery recycling machinery manufacturers is also very important. Our company specializes in recycling electronic waste and has won the trust and love of customers.

How do you choose the right lithium-ion battery recycling machinery manufacturer?

Choosing the right lithium-ion battery recycling machinery manufacturer is a process that requires comprehensive consideration of multiple factors. Here are some key considerations to help you make an informed decision.

First, evaluate whether the manufacturer’s technology is mature and reliable and whether it has independent technological innovation and R&D capabilities. Understand how their technology solves specific challenges in lithium-ion battery recycling, such as improving recycling efficiency, reducing energy consumption, and handling different types of batteries.

You research the manufacturer’s past projects and customer reviews, especially cases similar to your needs. Because market reputation and customer satisfaction are important indicators for evaluating the strength and reliability of manufacturers.

Most importantly, you compare the quotations of different manufacturers and evaluate the investment cost, operating cost and expected benefits. Then choose the solution with the highest cost-effectiveness ratio, while considering the possible additional costs and potential savings in the long-term operation process.

Finally, you can check whether the manufacturer has relevant quality management and environmental management system certifications, such as ISO 9001, ISO 14001, etc. These certifications are important proof that the manufacturer follows industry standards and specifications.

Yuansheng has more than ten years of experience and qualifications in lithium-ion battery recycling. And we have received wide praise and trust in the cases we cooperate with customers. This is all due to our professional team and high-quality electronic waste recycling equipment. If you are interested in us, please feel free to contact us.

Your Content Goes Here

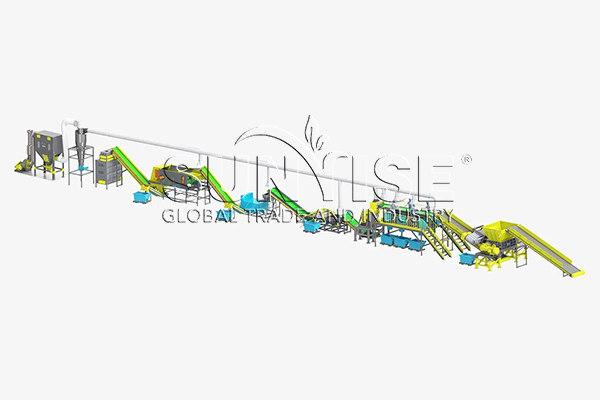

As the solar industry expands, solar panel recycling has become crucial to solve the problem of decommissioned panel disposal, protect the environment, and recycle valuable raw materials such as silicon, silver, etc. The recovery process includes pretreatment, separation, chemical treatment, purification, and strict control. This not only helps reuse resources and reduce environmental pollution but also has significant economic value. However, choosing the right solar panel recycling equipment is important. Because this can not only improve recycling efficiency but also save costs.

Four major factors to help you choose the most suitable solar panel recycling equipment Manufacturers.

You need to research the technology used by different equipment and its recycling efficiency. Therefore, give priority to equipment that maximizes material recovery while maintaining processing quality. Our solar panel recycling machine meets the above characteristics, using advanced disassembly, crushing, and separation technology to efficiently recycle discarded solar panels and obtain aluminum frames, glass particles, silicon, copper, and plastics.

In addition, evaluate your needs (now and in the future) and determine the minimum and maximum processing capacity of the equipment you need. Make sure that the equipment you choose can handle your workload. Our company can provide the most suitable electronic waste recycling equipment for you according to your specific needs.

Most importantly, consider the energy consumption and operating costs of the equipment, including power consumption, maintenance costs and necessary replacement parts. Choose equipment that is energy-efficient and has low operating costs. As a company with more than ten years of professional experience, we have cooperated with countless equipment companies, and all aspects can be considered for you.

Finally, you want to choose an equipment manufacturer with a good reputation and reliable after-sales service. Henan Yuansheng Company has more than ten years of professional experience, focusing on waste recycling machinery. We have a team of highly qualified engineers dedicated to providing first-class solutions. Also, if you want to learn more about the equipment, you are welcome to visit our factory and test the machines.

Contact Us

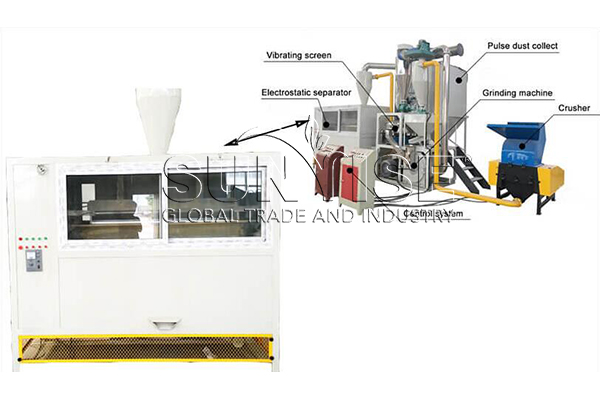

E-waste recycling equipment is a general term for a series of equipment and technologies used to process and recycle waste electronic products. E-waste includes old computers, mobile phones, televisions, refrigerators, and other electronic or electrical equipment. Since these wastes contain valuable metals (such as gold, silver, copper rare metals, etc.) and other reusable materials, you can recycle these materials through a special recycling process and gain economic benefits at the same time. In addition, e-waste recycling equipment usually includes crushers, sorters, magnetic separation equipment, electric separation equipment, dust removal systems, etc., which work together in the pretreatment, crushing, separation, and fine processing of e-waste.

What is the role of electronic waste recycling equipment?

- 1

Resource recycling

Electronic products contain abundant metal resources, such as copper, aluminum, gold, silver, etc., as well as non-metallic materials such as plastics. You can recycle these valuable materials through the processing of recycling equipment, reducing the demand for mining raw materials.

- 2

Environmental protection

If discarded electronic products are not handled properly, heavy metals and harmful substances will leak, causing serious pollution to the soil, water sources and air. Our electronic waste recycling equipment can safely handle these harmful substances, reducing environmental pollution and health risks.

- 3

Promoting economic development

The development of the electronic waste recycling industry can not only create employment opportunities, but also promote the advancement of related environmental protection technologies and equipment, which has a positive effect on economic development.

What are the main technologies of electronic waste recycling equipment?

Manual disassembly: This is a traditional technology that relies on workers to manually disassemble electronic products to recover circuit boards, metals (such as copper, and aluminum), and other valuable components. In addition, this process can effectively reduce the leakage of hazardous substances.

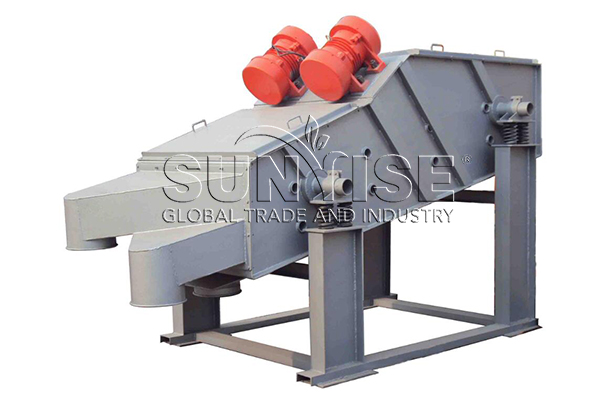

Mechanical sorting: In this process, you use sorting equipment such as magnetic separators, wind separators, and vibration separators to classify materials according to their physical properties (such as magnetism, density, size, etc.).

Low-speed crushing: You can use it to initially crush large pieces of electronic waste into small pieces for further processing.

High-speed crushing: You can use it to further crush the initially crushed materials into smaller particles for more precise sorting later.

Gravity sorting: Separation by using differences in material density, for example, separation of different materials by hanging or vibrating tables.

Electromagnetic sorting: Separation by using the electromagnetic properties of materials, often used to separate metal and non-metal materials.

Liquid medium sorting: Layering or separation of materials is achieved by using liquid media of different densities.

Optical sorting: Use optical recognition technology (such as infrared recognition, X-ray recognition) to distinguish different materials, especially suitable for sorting plastics and other non-metallic materials.

Contact Us

Waste recycling machinery manufacturers play a vital role in the current context of the increasingly serious global e-waste problem. E-waste recycling machinery manufacturers play a key role. Because it not only promotes sustainable development, but also improves e-waste recycling and reduces environmental pollution. Through innovative technologies and equipment, they have injected vitality into the e-waste recycling industry. In addition, they have also contributed to building a resource-saving and environment-friendly society.

Are e-waste recycling machinery manufacturers continuing to invest in research and development to promote the application of new technologies?

The technology and equipment for e-waste recycling are constantly developing and innovating, which can process and recycle e-waste more effectively and reduce the impact on the environment. Therefore, we have been actively investing in research and development and promoting the application of new technologies to improve recycling efficiency and environmental protection levels. Not only does this help advance our industry as a whole, it also better protects the environment and resources.

4 ways to be environmentally friendly with your equipment from e-waste recycling machinery manufacturers.

Exhaust Emissions

Our equipment is equipped with effective exhaust treatment systems that reduce or eliminate harmful gas emissions. For example, by using filters and adsorbents to capture and treat harmful gases such as VOCs (volatile organic compounds), etc.

Wastewater Treatment

Our recycling facilities have appropriate wastewater treatment systems capable of treating and purifying the wastewater generated. This includes removing heavy metals, organic matter and other harmful substances to ensure that wastewater meets discharge standards and does not pollute the environment.

Energy efficiency

Our equipment design focuses on energy efficiency, minimizing energy consumption by optimizing processes and equipment configurations. Thereby, you can achieve this by using energy-efficient equipment, adopting energy-saving measures, and optimizing work processes.

Hazardous material processing

Our equipment can effectively deal with harmful substances in e-waste. Such as lead, mercury, cadmium and other heavy metals. We therefore need to ensure that they are safely isolated and disposed of to prevent impacts on the environment and human health.

Contact Us

The recycling of electronic products is an important task related to resource reuse and environmental protection. Recycling electronic products can promote resource recycling and reduce resource waste and environmental pollution. The best methods for e-waste recycling are therefore of great importance.

What are the most commonly recycled electronic devices?

The most commonly recycled electronic devices include mobile phones and smartphones, computers and laptops, tablets, televisions, and monitors. In addition, household appliances, digital cameras, and camcorders are also frequently recycled.

How to establish advanced recycling facilities and technologies?

The most commonly recycled electronic devices include mobile phones and smartphones, computers and laptops, tablets, televisions, and monitors. In addition, household appliances, digital cameras, and camcorders are also frequently recycled.

Invest in R&D

Invest a lot of money and resources in R&D to develop new recycling technologies and facilities to improve recycling efficiency and quality.

Resource integration and cooperation

Collaborate with other businesses, institutions and governments to share resources, technology and experience. Because such cooperation helps to achieve resource integration and improve recycling efficiency.

Green design and production

Optimize the layout, structure and process of recycling facilities using green design and production concepts. Therefore, you can reduce energy consumption and environmental pollution.

What is the best way to recycle e-waste?

The best way to recycle e-waste is to adopt an integrated e-waste recycling system. For example, the following aspects.

Policies and regulations

First, establish a sound policy and regulatory framework. At the same time, clarify the responsibilities and obligations of e-waste recycling. Finally, you should encourage businesses and individuals to participate in recycling.

Ensure safe handling

Ensure that recycled e-waste meets environmental and safety standards during disposal. Thus, you can avoid negative impacts on the environment and human health by participating in recycling.

Provide convenient recycling channels

Provide convenient recycling channels, such as setting up e-waste recycling points in supermarkets, office buildings, and schools. Encourage the public to actively participate in recycling activities through these accessible options.

Publicity and education

Through publicity and education activities, we will increase public understanding and awareness of e-waste recycling and strengthen support and participation in e-waste recycling.

International cooperation

Another point is to strengthen international cooperation and jointly deal with the e-waste problem. Such as knowledge sharing, technical exchanges and collaborative research, in order to jointly promote the development of global e-waste recycling.

Contact Us

Furthermore, we offer different recycling equipment and solutions for various types of e-waste. So our company can fully meet your needs. However, recycling e-waste brings many important benefits. I will introduce the benefits of electronic waste recycling in detail below.

Resource reuse

E-waste contains a large number of valuable rare metals and other resources, such as gold, silver, copper, aluminum, etc. This recycling of waste effectively recycles and reuses a valuable resource. This reduces the consumption and exploitation of natural resources and helps to protect the environment.

Environmental protection

E-waste contains many harmful substances, such as lead, mercury, cadmium, etc. These substances can cause serious pollution to soil, water sources, and air. By correctly recycling and processing these harmful substances, you can avoid the harm they cause to the environment and reduce pollution.

Data security

E-waste may contain a large amount of personal and sensitive data, such as bank account information, passwords, personal photos, etc. By correctly recycling and processing, you can ensure the safe destruction of this data and protect personal information.

In the process of recycling electronic waste, how to ensure the effective recovery and reuse of rare metals and other valuable resources in the waste?

Perfect recycling technology

Because our company has advanced recycling technology, it ensures efficient extraction of rare metals and valuable resources.

High-efficiency recycling equipment

Our company has established a cooperative relationship with a number of electronic waste recycling equipment. More importantly, we focused on improving the efficiency of e-waste recycling, and achieved remarkable results. What’s more, we offer different recycling equipment and solutions for different types of e-waste. Therefore, our company can fully meet your needs.

Improvement of the recycling industry chain

We have a complete e-waste recycling industry chain, including recycling, sorting, dismantling, refining and other links to ensure that resources can be effectively recycled and reused.

Contact Us

With the development of technology, electronic devices play an important role in our lives. However, the massive generation of electronic waste that follows poses a serious threat to the environment and human health. Therefore, proper disposal of electronic devices becomes crucial. So this article explains the importance of proper disposal of electronic equipment and how to take steps to achieve effective e-waste management.

How can you safely dispose of your waste electronic devices?

It is very important to dispose of electronic equipment safely. Here are some suggestions.

Back up and delete all personal data.

Find the right e-waste disposal method.

Find a trustworthy recycling center or service provider.

Do not throw away or dump electronic devices carelessly.

Participate in an electronic equipment donation or recycling program.

Ensure that you disassemble and handle equipment correctly.

Which machines do you can need for disposing of waste electronic equipment?

Our company uses electronic waste dismantling equipment and crushing equipment to deal with waste electronic equipment. In addition, there are screening equipment, magnetic sorting equipment, dust removal equipment and other machines. The corresponding electronic equipment recycling equipment will also vary depending on the type of electronic equipment. If you are interested, you are welcome to consult us in detail.

Which machines do you can need for disposing of waste electronic equipment?

There are two main reasons why e-waste needs to be disposed of properly.

E-waste is potentially valuable to recyclers. Because older electronic devices contain materials like copper, aluminum, lithium and gold. Therefore, recycling these materials minimizes the extraction of original resources and saves energy.

Electronic devices contain toxic substances. Especially lead and arsenic. If it is in a landfill, then these substances will leach out. So it poses a threat to people and wildlife in the area.

What potential threats does e-waste pose to the environment and human health?

The potential threats posed by electronic waste to the environment and human health include: soil and underground contamination, air pollution, health hazards, resource waste, and ecological damage.