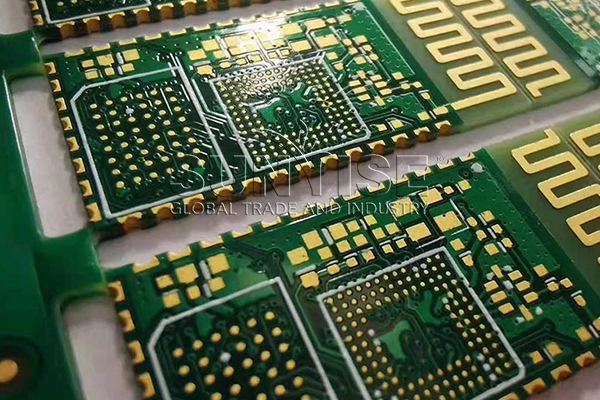

In fact, the PCB recycling machine is a special equipment for disposing of discarded PCB boards. In detail, the waste PCB board is mainly processed by physical methods through the pcb recycling machine. As a result, materials such as metals, plastics and glass fibers can be efficiently separated and extracted. In most cases, the treatment process includes steps such as crushing, screening, sorting, etc. Therefore, the reuse of various materials in the waste PCB board can be realized. It can be seen that this is not only conducive to reducing resource waste, but also conducive to reducing environmental pollution and promoting sustainable development.

How should you recycle circuit boards?

You can understand how our pcb recycling machine works from these four parts.

First of all, the PCB recycling machine uses two ways of electric heating and liquefied gas heating, which is to control the internal temperature at about 150 ° C. This loosens the tin on the circuit board. As the disassembly machine rotates, the circuit boards rub against each other, and the circuit boards rub against the cylinder wall in the same way. As a result, electronic components fall off when the host is running.

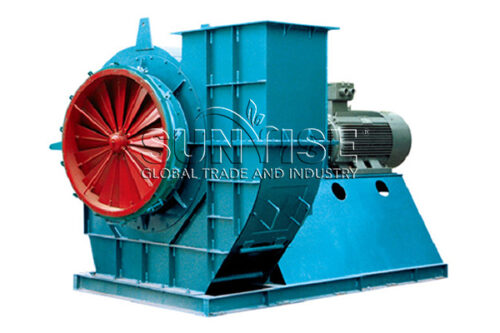

Crushing equipment

Equally important, the crushing equipment can crush the waste circuit board and actually crush it into small particles or powder. Therefore, it is convenient for subsequent processing and recycling.

Collector

All in all, the circuit board recycling machine mainly separates the material gas and collects the powder for centralized treatment. It mainly includes collector, discharge valve, powder storage tank and so on.

Screening equipment

The screening equipment is mainly used to screen and classify the waste PCB board in order to separate the materials in the PCB board for further recycling. In addition, the screening equipment separates the metal, plastic and glass fiber materials in the PCB board through physical methods such as vibrating screening and air separation. As mentioned earlier, this process makes recycling more efficient and precise.

Which of our environmental protection equipment do you use in the PCB recycling process? what is the function?

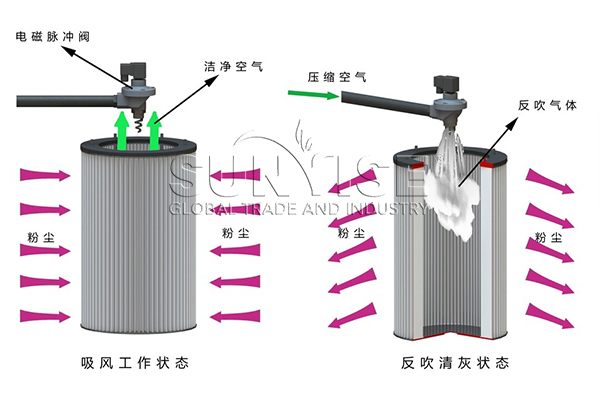

Basically, the pulse dust collector (pulse purifier) is the only pcb recycling equipment. Specifically, the PCB recycling device utilizes the pore and fiber structure of the filter material. And then this structure helps to filter and remove dust from the air.The functions of the PCB recycling equipment are introduced in four parts.

Dust purification

Due to the PCB recycling process will produce a lot of dust and particulate matter. Therefore, the pulse dust collector is needed to collect and filter the dust in the air and purify the air, thereby reducing the impact of dust on the environment and the human body.

Maintenance equipment

In addition, some sensitive components in PCB recycling equipment are susceptible to dust. This can result in damage or reduced efficiency.In this case, the pulse dust collector can reduce dust accumulation, thereby protecting the normal operation of the recovery equipment. Moreover, it can also extend the service life of the equipment.

The two functions of the pulse dust collector.

Simplified clean-up work

The pulse dust collector collects dust into the dust collector. Therefore, the cleaning work is more convenient and efficient.

Environmental protection

More importantly, the use of pulse dust collector can effectively control the diffusion and emission of dust, thereby reducing environmental pollution.

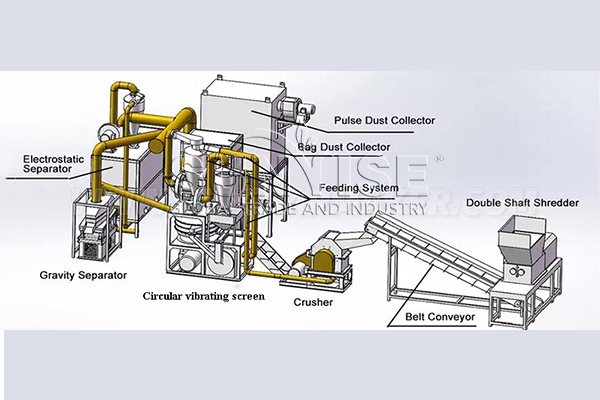

What is the working process of our circuit board recycling machine?

This is the correct use process of the PCB recycling machine. According to these sequences, you can complete PCB recycling.

Shred the bare board to 2-3 cm.

crush the crushed circuit boards to about 20 mesh.

At the same time, the crushed material is sifted and can basically separate the resin, copper, dust and fiber. Specifically, dust and fibers are sucked into the collector by the induced draft fan, and resin and copper enter the grading screen.

Collects dust and ultrafine fibers generated during the crushing process.

Screen resin and copper. First the unseparated resin and copper are returned to the host for further crushing. Then the separated resin and copper enter the specific gravity separator for sorting.

The resin powder and copper are sorted by specific gravity. Since the weight of copper is greater than the weight of resin, copper will be sorted to one side and resin to the other side. This achieves the separation of metals and non-metals. This is currently the most advanced technology in the country and can achieve a metal sorting effect of more than 99%.

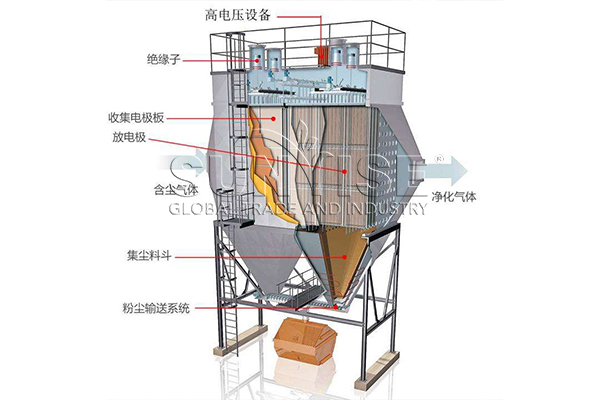

Only through the specific gravity sorting machine materials can be high-voltage electrostatic separation, separating the small copper powder and resin contained in the material (the principle of high-voltage electrostatic separation is: through the transformer to adjust the input power to 100,000 volts of high pressure, the formation of high-voltage magnetic field, conductive metal has adsorption effect, so as to achieve the separation of metal and non-metal)

Collect dust and fibers, and discharge the collected fibers.

What materials can you recycle using our circuit board recycling equipment?

PCB recycling machines can obtain these four major categories of materials.

Metal

First of all, remember that the metals in the circuit board are mainly copper, iron, aluminum and tin.Of course, through the crushing and separation process, companies can extract the metal from the circuit board. They can then choose to reuse or sell it.

Organic matter

In addition, the organic matter in the circuit board mainly comes from the substrate, circuit protective layer and other components. If properly treated, the organic matter can be recycled. For example, as fuel or chemical feedstock.

Fiberglass

Second, the circuit board usually contains fiberglass to strengthen the structure. Therefore, after crushing and recycling, the manufacturer can separate the glass fiber and reuse it, thus producing the fiber material again.

Plastic

How to ensure the safety of using PCB board recycling machine?

In any case, to avoid personal injury and environmental pollution, please follow the following safety precautions when using the PCB recycling machine.

Before performing operations on the device, you need to check and maintain the device to ensure that it runs properly. Because to avoid equipment failure caused by security accidents.

When using the circuit board recycling machine, you must first remember to wear relevant personal protective equipment, such as safety hats, goggles, gloves, etc. Because this will help protect your head, eyes and hands from potential harm.

When operating the equipment, it is essential to first ensure that there are no obstacles or flammable materials around the equipment. Secondly, it is important to maintain good ventilation in the area.Only in this way can fire or other safety incidents be prevented.

After you have cleaned and maintained the equipment, it is important to properly store it in a safe condition. Because this will help prevent potential safety hazards that may arise from long-term idleness or lack of maintenance.